What All Precaution Should You Take for Installation and Maintenance of Air Conditioner?

You have a new air conditioner for your room and it is installed. You want to test if everything is working fine with it like most people do by making sure there is proper cooling. However, sometimes things don‘t go as planned and issues arise post installation which could be due to poor installation practices or bad service after the sale. This blog post will try to provide you some key tips on what you should take care of while installing and servicing your Air Conditioners so that hopefully these issues won‘t happen again in the future.

The right selection of installation location and quality of installation work

Most people don‘t know where the best place to put their AC unit is and will go along with whatever the installation technician says. It‘s important to be aware of what your needs are and be able to talk to the person installing it about those needs.

The important things to keep in mind are:

Window AC

- Window AC shall be installed on the top of the window so that cool air, being heavy, settles downward and thus creating its own cool airflow cycle. In case, an opening is already provided in the wall for its installation, then better to prefer the same location.

- The window dimensions of 1.5 T AC is 660×430 mm and depth may vary from 700 to 780 depending on the star rating i.e. in 5 stars the additional volume required for the condenser is achieved by increasing the depth.

- For below 1.5T, some brands have maintained the window dimensions whereas others have reduced size. In such a case, before buying or delivery one should modify the window by inserting aluminum/wooden panel so that mounting is secured on all three sides. Otherwise, the installation technician will mount it on two sides and fill up the gap on the third side with some cardboard for insulation. This may become a source of vibration in future.

- For condenser cooling, the air is sucked from three sides and if the gap is not adequate as recommended by the manufacturer, then the efficiency of the condenser will be affected. Hitachi recommends 200 mm on right and left and 100 mm on the top. If you look around the installation of AC, you will find this requirement is not observed in many of the installations.

- For smooth flow of the condensate to the drainpipe, the AC installation is with an inclination to have a gap of 10mm up at the front-bottom. Be careful to ensure smooth flow of condensate to the drainpipe otherwise you will experience rusting issues after 3-5 years.

- Avoid fall of direct sunlight over the condenser as it is likely to affect the condenser efficiency during peak summer and you will experience poor cooling. For this, better to have a sunshade on top of the window AC. For this, mounting on the top of the window is preferred so that sunshade can be installed. Be careful that sometimes the gap is used by pigeons to make a nest.

Buy at Amazon: Window AC Cover, Sun Protector Shield for Window AC and Outdoor Unit

Split AC

One should identify the location for the installation of the outdoor and indoor unit. The location preferred is

- It should be easily approachable from the balcony, window or surface platform for cleaning and servicing when required. Ensure that there is no direct sunlight falling on the outdoor unit as it will impact the performance of the condenser. If unavoidable, better have a sunshade on top of it.

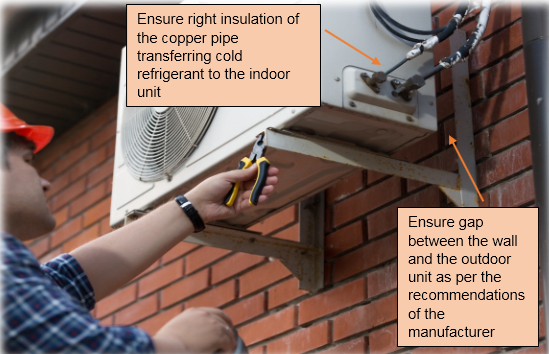

- Ensure that the installation technician maintains the recommended gap between the wall and the outdoor unit for the condenser fan motor to create adequate airflow over the condenser;

- There are two pipes of refrigerant connected to the outdoor unit, one bringing the air to be cooled and another taking away the cool air to the indoor unit. You must have noticed black foam type insulation called Rubatex and generally, the installation technician does not ensure the insulation right from the pipe and always leave some portion open as shown in the picture below. One should watch and ensure proper insulation otherwise it will affect condensation and water-dropping during service and loss of efficiency.

- The condensate from the indoor unit shall be collected in the drain pad and moves without obstruction otherwise it will result in water leakage and the damage to the wall requiring extensive repairs.

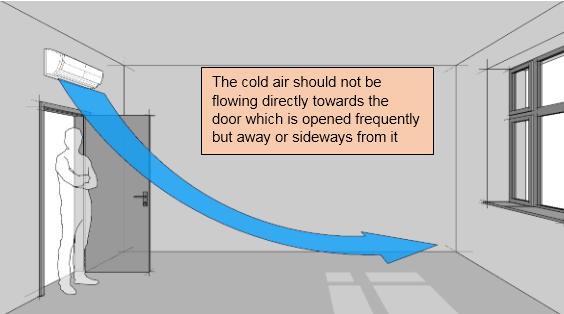

- The mounting of the indoor unit shall be on the wall so that the airflow is not directed towards the main door of the room but away or sideways otherwise the leakage of cold air from the room will increase. The installation shall be preferred as shown in the figure below.

Final Checking and measurements

Check the following after the installation is completed –

- Input voltage

- The Current taken by the machine when the compressor is running and when the compressor is not running. The current taken when the compressor is running is mentioned on the nameplate of the unit and shall not be more or less and be within plus/minus 5%;

- The temperature at the suction side and the temperature on the outflow side.

Keeping record of these measurements help in evaluating after the next service. In fact, whenever you observe the power consumption in a month is more than the corresponding month of last year, there is every possibility the AC needs servicing and record of these parameters will help.

AC Maintenance

AC requires schedule maintenance mainly for cleaning, checking for current it draws to indicate whether the gas pressure as per the originally filled. Poor maintenance can lead to less cooling and more electricity consumption.

Why you should be vigilant during AC servicing:

While booking for the maintenance, observe the cleaning work to ensure the cleaning of the coils is done to the best possible standard. There is a prescribed proforma to be filled by the technician about the job done and its observation on the various measurements done particularly the current drawn by the unit when the compressor is working and when not. Make sure that form is filled up so that the same can be compared before and after the next service.

Except cleaning there is no other preventive maintenance schedule for AC.

Gas leakage:

After 5-6 years of service, the rubber mounting, rubber parts used for any securing purpose may get deteriorated and a check may be done when the service is done. If there is deterioration it may result in vibrations, and here is a possibility of brazed joint giving way for leakage.

There are also issues raised by our reader that due to passing of drain nearby, the pollutant environment resulting in the corrosion of the pipelines and thus leakage. At the time of purchase, one should be careful to go for Cu pipe and to understand the features one should read our post “Air Conditioners: Copper Coil vs Aluminium Coil”.

Dring repair of gas leakage by brazing, if proper care is not taken, then the heat may result in other joints getting loosened. It happens many a time that once there is a report of gas leakage, it repeats very frequently.

Insulation:

Make sure that the insulation of connecting pipes is well maintained as loss of insulation can lead to reduced cooling, high electricity consumption and water drops from the AC. Every time servicing is done, ask the technician to make sure that insulation is proper.

Conclusion

It is not just important to buy the right product, but it is also important to make sure that the installation happens properly and the product is maintained well. A well installed and healthy AC can give good cooling with less electricity consumption, but if it is not installed properly or taken care of, it can result in dissatisfaction from a good purchase.

About the Author:

Mr Mahesh Kumar Jain is an Alumnus of the University of Roorkee (IIT Roorkee) with a degree in Electrical Engineering who has spent 36 years serving the Indian Railways. He retired from Indian Railways as a Director of IREEN (Indian Railways Institute of Electrical Engineering) and has also served as Principal Chief Electrical Engineer at many Railways. He has performed the responsibility of working as Electrical Inspector to Govt. of India. Mr Mahesh Kumar Jain is having a passion for electrical safety, fire, reliability, electrical energy consumption/conservation/management, electrical appliances. He currently serves as a consultant at Nippon Koi Consortium in the field of power distribution and electric locomotive. More from this author.